Rerurn to Romy the Cat's Site

In the Forum: Horn-Loaded Speakers

In the Thread: Practical Guide for Back Chambers Tuning.

Post Subject: Test Plug for PipesPosted by Kcct82 on: 11/9/2008

fiogf49gjkf0d

Hello Romy,

I've given back chamber tuning some thoughts and the biggest pain in the a$$ is to create a SIMPLE mechanism to change chamber volume fast while providing tight seals. What do you think about using test plugs from plumbing supplies...?

The biggest plug I found is 8" in diameter and 3¾" thick (probably be 2" thick after compressing the rubber to form seals). The Max Back Pressure it will hold is 17 PSI, do you think it'll be enough to with stand 8"-15" driver's midbass horn pressure?

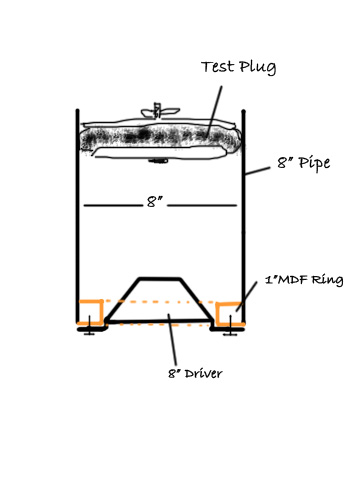

Construction is pretty straight forward, if you're using an 8" driver, simply buy an 8" plastic pipe and cut to desire length (the longer the pipe the bigger the back chamber you have duh...) Route an 8" outter diameter ring from MDF with whatever inner diameter your driver fits to secure the driver to the 8" pipe. You now have everywhere sealed except for the back where you can use the 8" test plug to fine tune chamber volumn.

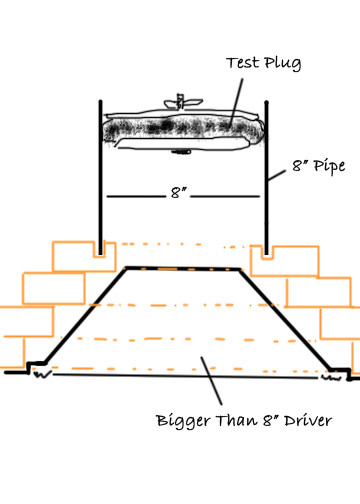

For bigger drivers you can route multiple 1" thick rings to step it down from say 15" to 8" and connect the 8" pipe.

Keith

Rerurn to Romy the Cat's Site