Rerurn to Romy the Cat's Site

In the Forum: Horn-Loaded Speakers

In the Thread: Macondo's Axioms: Horn-loaded acoustic systems

Post Subject: The issues that did not make the Macondo's Axioms.Posted by Romy the Cat on: 4/6/2008

The Macondo's Axioms are the concepts that I employed to make Macondo but it does not mean that Macondo takes care about all things that are I feel are important. Some important this were intentionally left out the Macondo’s and mine attention. One of the problem is what Be describe – the mouth’s edge distortions due to the discontinuity of horn. It is important subject but Macondo's deals with it in a way ignorably. One of the best ways to deal within horn’s edge problems is to use LeCleach profile. It should be better solution for HF. The Macondo's tweeter went to a full length to deal with the horn’s edge problems having the Water Drop shape or the whale body shape. The Macondo's MF horn just ignores the problem completely…. and it doe it absolutely deliberately.

The consideration I took do not deal with MF horn’s edge problem is because the LeCleach profile with its negative opening takes more vertical real-estate to implement. To run LeCleach profile at my MF 400Hz horn I would loose approximately 3” to implement the negative opening. What you go for implementation of 5-way multi-wave horns and you objective is to be able to INTEGRATE THEM IN EXTREME NEARFIELD then each inch in vertical plane became very countable. If I use my horns from 15-20 feet then I would go for LeCleach-like solution and hive to horn more space to birth. However, since I am at 9 feet I am at very different restriction to vertical integration and 3” are too important for me. So, I feel that benefits for narrowing the vertical window are more important than the hassles I might pick from horn’s edge. So, as the result the edge of the Macondo’s MF horn is made for vertical compression.

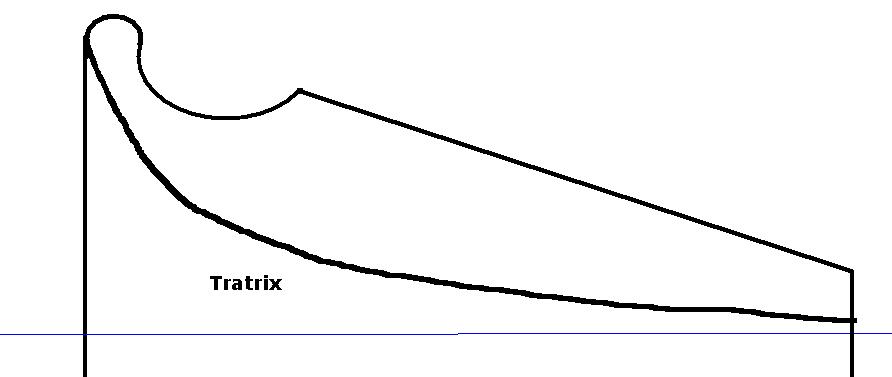

I have to admit that when I ordered the Macondo’s MF horn in 2001 from John Hasqiun and requested the profile as is then it all was not in my head. I was much-much less experienced with horns then and drown that profile just because I looked sexy to me. Accidentally that “sexy” profile is allowing having the best vertical space compression. So, I did not change it for years. Would I change it? Yes I would. A year or so ago, what I was thinking about my Water Drop tweeter I came up with a new edge profile for MF horn that deals with the horn’s edge problems but do not consume space as LeCleach does. Below is the depicting of the idea. I did not try it but it should work. Sometime in future when I have a good horn maker whom I would be able to torture I am planning to convert my current MF horn into this profile. Since it a first time I make it public I would like to grand a name to this way of horn termination. I would like it to be called the “Water Drop Edge“

Now, about your idea of doing that:

“ Place triangular pads of felt of suitable size and thikness, at the horn wall at the perimeter but still inside the horn.”

This is VERY good idea and I have a lot of talk about it during the last years. In facts some of the versions of your idea I intend to try sometimes. The idea was introduced to me by Bud Purvine and his EnABL Patterns

http://www.romythecat.com/Search.aspx?UserID=155&Phrase=

This is very interesting subject, thoght Bud attacks the boundary problems, wich is looks like a diferent thing (they migh not me). Talking with Bud I figure: why do not use the very same random patterns at the edge of the horn to (I quote you) “to smear out the diffraction of the wave [at the edge] in time and space, and maybe render it harmless. “

Bud, uses paint of different heaviness to deal with the drivers’ cones. In our case it might be any material randomly extending over the profile of the horns edge. Manipulating by profile, height and material of the “edge pimples” I think it might be possible to very interning result. I DI NOT trey it myself but I keep my mind very open toward the Budanization of the horn’s edge

Rgs, RomyRerurn to Romy the Cat's Site