Through membrane movement interlacing there are more bass, due to the bass

horn mouth distance, there's no rise above 100 Hz. So the pressure chamber can

be kept extremely small, both horns are extremely small. Small is also the air mass

in the horn and the wall-to-wall distance inside the horn is short, the relatively

small cabinets also contributes to the fast, contoured bass reproduction.

| |

| | | | | | | |

|

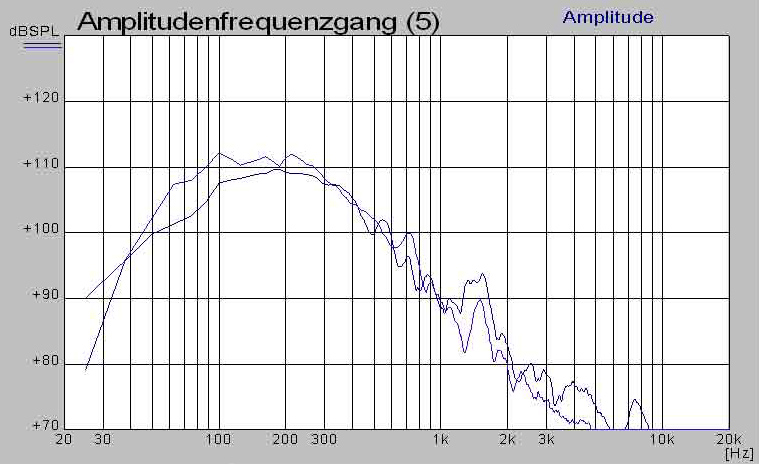

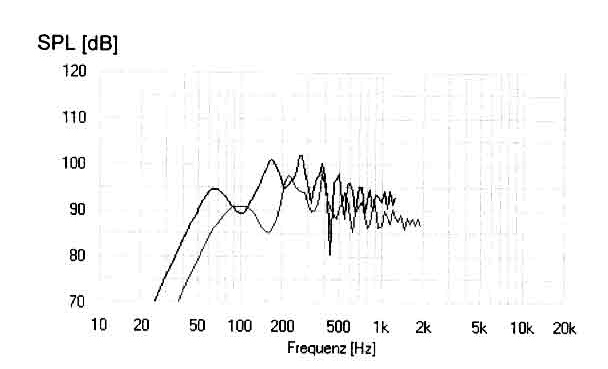

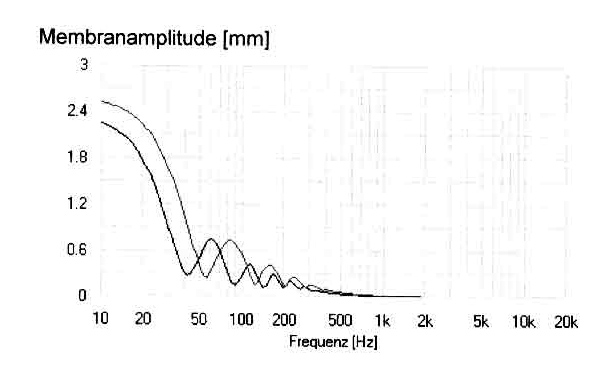

An attempt to explain

these graphs:

By way of parallel

operation of the two

different horns, the

driver of the long horn

controls the stroke of

the driver in the short

horn. The little horn

will not be acoustic short

circuited, but instead

creates sound pressure,

amazingly much, more

pressure than the long

horn below 40 Hz.

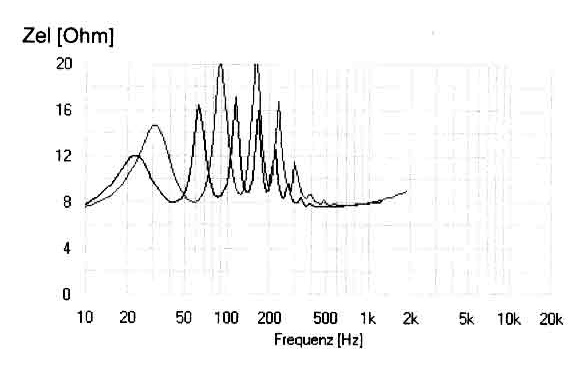

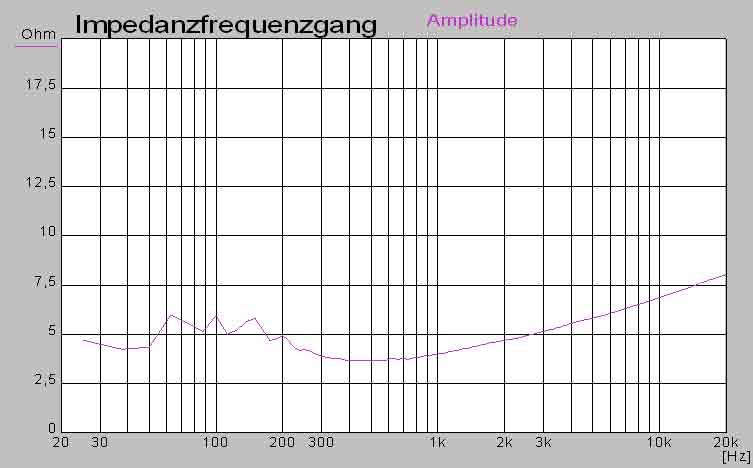

At the same time, the

impedance peak of the

lowest octave is eliminated

by non-interlacing,

below 50 Hz~4 Ohm.

See system horn mouth

measurement and single

simulation of the

CORNET and impedanz. | |

| |

| |

|

Membran movement

interlacing:

My haptic verifications

show a rather linear

membrane movement,

similar to a normal

distribution curve.

Which means a reduction

of "pressure changes",

and hence less mechanical

membrane stress and

maximized |