Rerurn to Romy the Cat's Site

In the Forum: Horn-Loaded Speakers

In the Thread: Midbass Horns and Real Estate.

Post Subject: A proper commercial midbass horn, sort of....Posted by Romy the Cat on: 8/5/2009

fiogf49gjkf0d

Since I started this thread I have received a number of emails from people bitching that I do not like this, criticize that and that they can’t figure out what I do like. I reply to them invariably – “Do not read my site as you are too much a Moron”. However, besides the devaluing a “secretive” fact that there are plenty of idiots who visit my site there is a useful side element among the inquiry that those people ask and the question would be – are any properly made commercial midbass horn available out there?

It would be safe to say that I know probably all public commercial midbass horn available and frankly I do not like any of them. It is not that that all of them sound bad (and most of them are) but rather from a perspective of conceptual architecting not of the commercial midbass horn appears to me. As I said before - I want full length, small through, sufficient mouth, no chambers, no steps, properly continuing-expending slow profile. Any anyone does it commercially? Nope, everyone cheat.

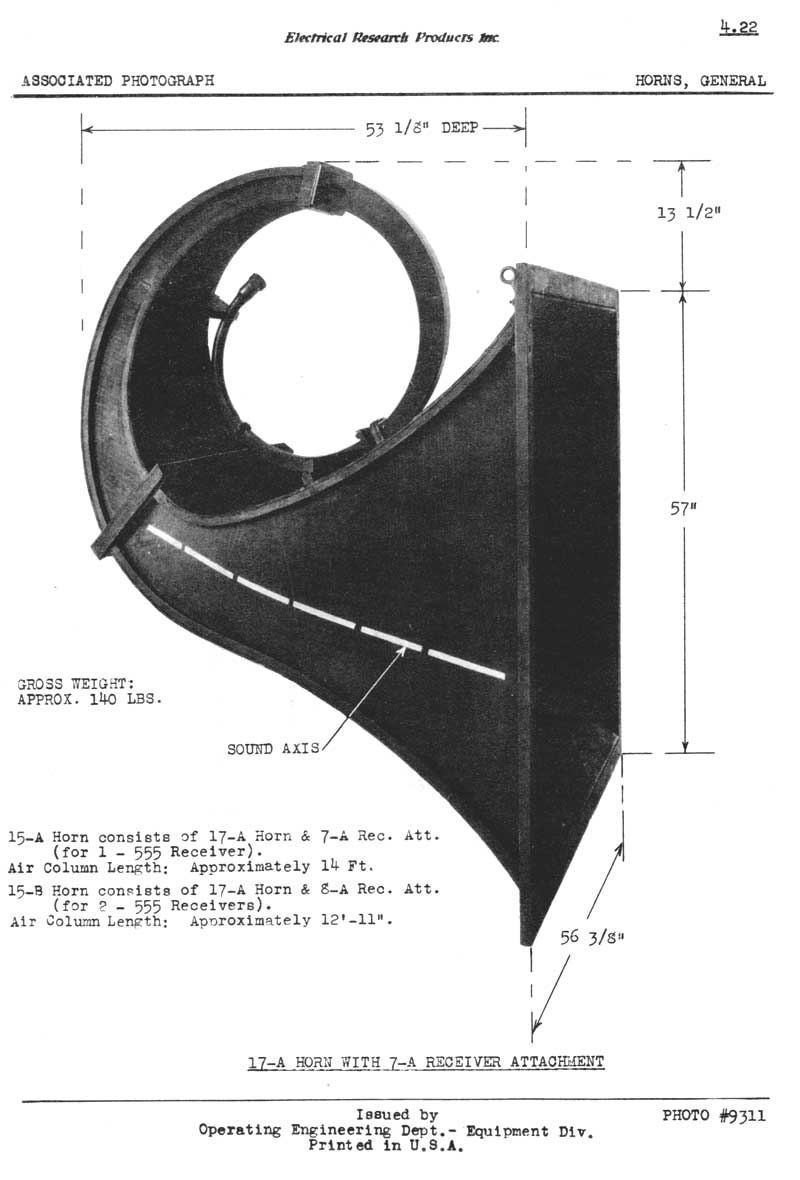

There is only one commercial midbass that remotely fulfill all my demands. I am taking about Western Electric 15A horn. Then 15A is well-know horn with 57x57 mouth and with a very properly made continually-curving neck.

http://www.audioanthology.com/building.htm

http://www.moviemice.com/we/horns/index.php

it has all attributes to feet my bill of being good horn.

Still being the most properly made among the much worse midbass comparators I am not in complete agreement with what 15A does and would like not to repeat their mistakes. The 15A has near 60Hz mouth but was designed to use with WE555 driver that feel hardly comfortable at 100-150Hz. The 15A has a presses stress zone at the last bend. The 15A has a bit too low level of horizontal expansion. And in the end the 15A is something that I call wall-stressed horn. The wall-stressed horn is a horn where circumferential force not evenly presses one side of horn bell. The sound that runs across the 15A horn is like in centrifuge pressed to the outer skirt. The presence of the wall-stressing itself is not so bad - the question is how the stress is handled. If it handled with proper dumpling or proper mass-lording of the stressed surface then it is OK. The 150 point of the 15A is not nearly enough to handle the circumferential force of pressure so the 15A sounds as good as many butterflies will lend atop the 15A while it is working. Sure, there is no “movement of air” in horn a horn and the circumferential force in horn might be visualized only conceptually. I do not have data or evidence about the different pressure in the wall-stressed horns. But I do know that wall-stressed horns with all the rest equal conditions do sound always more surface-colored then horn with mouth that have no pressure obstacles or stressed walls.

What is necessary to make the 15A to sound better then it is. The 15A must weigh 800 pounds for start and the walls shall be 4 times thinker. Alternative to the beefing up the horn wall would be axis-curving of the stressed surface. In this approach the stress will not be applied to the flat surface as it is done in 15A but despaired across curve that located transversely to axis of the horn (the way how it done in Silbatone‘s Aporia). The last curved need to be slightly smoothed up. A ultra-low- exertion driver, capable for full 50Hz , good TTH characteristic, with the same little throat has to be found - good luck with this one! The 15A as it now shall be OK sounding horn - primary because the small throat and slow horn rate. Could it be better, I bet it might. Still, as it is the 15A probably the less problematic commercial midbass horn among all made.

What would be fun if someone would make the replica of 15A only magnified twice larger! That horn will be able to go an octave lower, will be able to use 4-5” throat with more LF able driver. And the most important is that it will be able to have more space in the curved neck and everywhere else to make the walls of this larger horn very tough and very stiff. If somebody makes a pair of those 1000 pounds double-size 15A horn then invite me – it would be worth to listen. I just afraid that to make the double-size 15A horn will be for somebody much harder than to make the same straight horn.

Rgs, Romy the CatRerurn to Romy the Cat's Site