|

Posted by haralanov on

01-05-2009

|

|

fiogf49gjkf0d In the thread “Exceptional loudspeakers drivers” Paul S. wrote:

"LOTs of time pretty much wasted lately, looking at "HE" direct-radiator drivers that are actually only HE at their uppermost frequencies, with diving responses and large-to-huge power "ratings" that allow the "pros" to simply turn up the heat to get anything approaching LF via ANY means. Also, and at least as annoying, even smaller upper bass/mid drivers have the same rising-with frequency curves that make their "efficiency ratings" silly, at least in practical terms, or when viewed in the context of HE and/or the putative useage of the driver in question."

Unfortunately, this is always the case with high BL drivers, because the back EMF which is generated by the movement of driver’s voice coil is too high and it acts as a electromagnetic break for the excursion of moving parts at lower frequencies. Direct radiators with too high magnetic flux or too long voice coils (having more turns) do not have “proper” balance between fundamentals and harmonics and that’s the reason why they sound so dry and thin if they are not horn loaded. The key is to have optimum BL factor and only then the driver will have good tone. This is always the case, especially with bass drivers. I laugh very loud each single time when I see somebody use woofers with 1,5-1,8T in the gap as wide range direct radiators. That’s the worst case because people read in the the driver’s specifications it has 98+ dB sensitivity but they do not know that this number is valid only at the upper range of the driver’s bandwidth. The result bass which is more dry than Sahara wind at 3p.m. at the summer, which is very very far from the real acoustic bass, but the morons seems to love it… Ironically to get a good sound of HE direct radiator is not an easy task and may be it’s even impossible if the driver is used in more than 2 octaves.

Let look deeper at the subject and analyze the different ways for achieving high efficiency.

1) To raise the diaphragm diameter. This way the efficiency of the lower octaves is raised, but the good sound in upper spectrum gets killed, because the break-up of a large diameter membrane is always lower in frequency compared to a small diameter one. The resulting frequency response seems good on paper but in reality the reproduced sound is not music related any more cause there are a lot of low amplitude resonances thus the driver becomes tonally blind at HF.

2) To lower the moving mass. If the diaphragm/voice coil former are made thinner, we have issues with mechanical rigidity, thus instantly killing the transparency of upper frequencies. With lowering Mms, the resonance frequency gets higher, so actually this method lowers the efficiency in the bottom octaves.

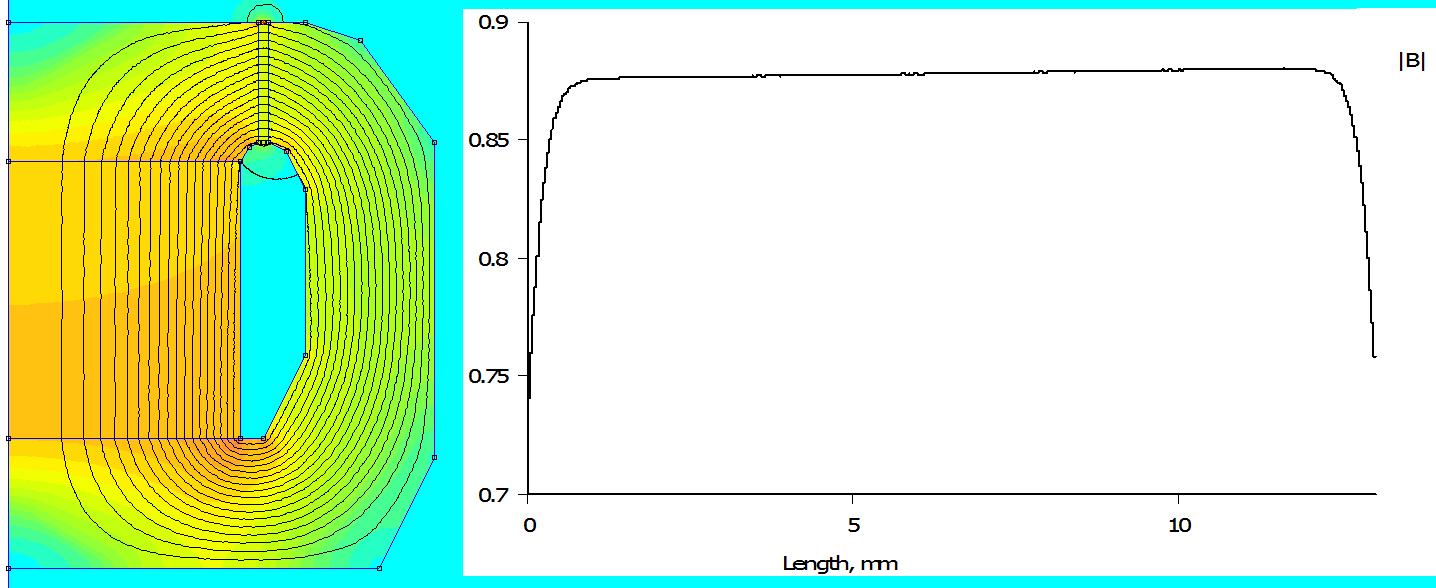

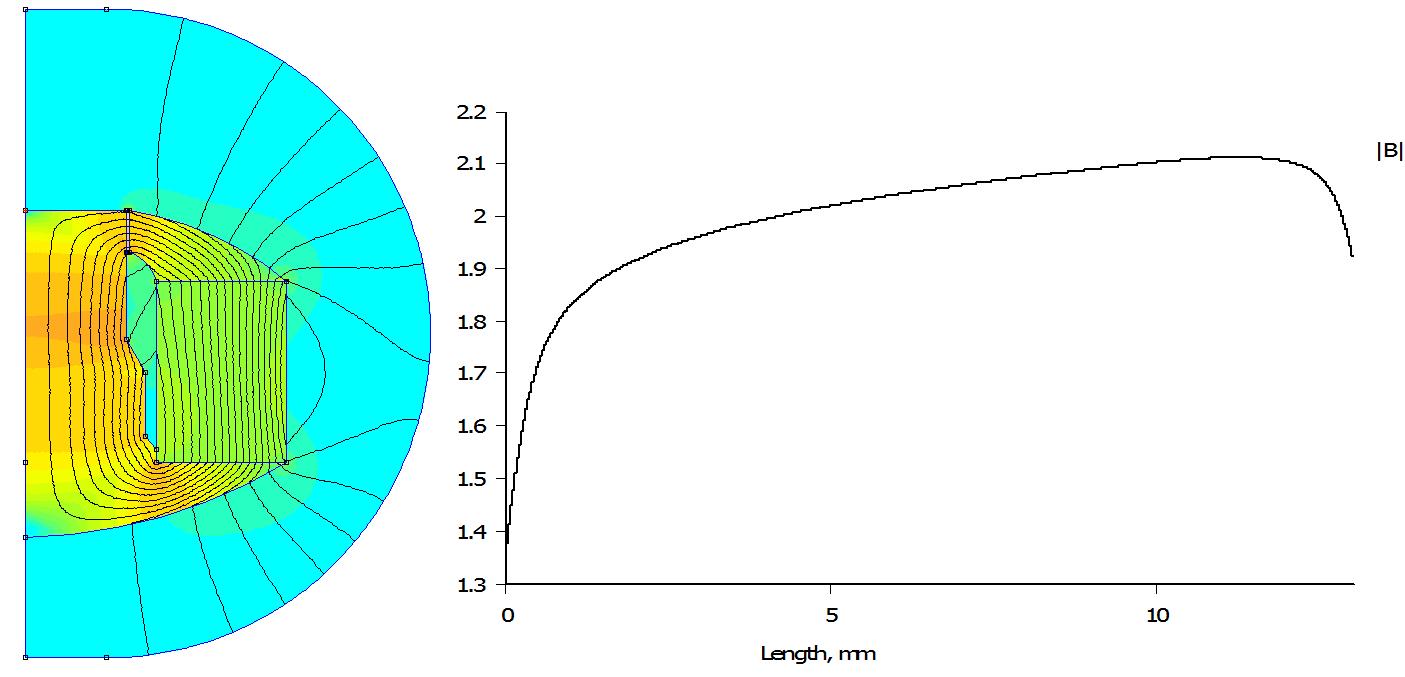

3) To use more powerful magnet system. If the main objective in driver design is maintaining low distortion levels, it is not possible to achieve linear magnetic flux across the whole length of the magnetic gap and in the same time having high flux density. Lowering the distortion levels to an absolute minimum is only possible if the voice coil always “see” constant magnetic flux in it’s Xmax limits. The only solution for this to be valid is using underhung design. But this method eats sensitivity because 40-50% of the flux is not used at all. Let look at the the illustration below. Magnet system is designed to be very linear, while in the second illustration (magnetic circuit design courtecy of Steen Duelund) the design objective is achieving very high flux. Both of the designs has 13mm high gap (1mm wide).

The linearity differencies between the two magnet systems is obvious.

4) To use a voice coil with more turns. Unfortunately this is also compromise because this way moving mass gets higher. The only alternative is to use thinner conductors but this way the dynamic compression is happening even at few watts of power in the coil and the driver have good sound only at low levels.

5) To use softer suspensions. Ohh... :-) This way the driver will have higher amplitude at lower frequencies but there will be issues with damping of the cone movement. Listen to loudspeakers build around Accuton bass drivers and you will understand why this is not acceptable.

So it is very very very hard to design a really good sounding and capable driver, used as direct radiator, and at the same time to have high sensitivity… Here comes the horn-loading and suddenly all of the above mentioned problems gets suddenly evaporated :-)

Best Regards,

Petar

|

|

|

|

Posted by Romy the Cat on

01-05-2009

|

|

fiogf49gjkf0d Yes, Petar

I would agree with the most but with horn-loading all compromises suddenly do not get evaporated. The horn is not a panacea as the horn-loading is basically as well bandwidth-limited. In fact for objectivity sake I might say that the direct radiators might be even are more flexible to address the problems you mention above. The direct radiators are small and therefore they might be multiplied. 2, 4, 6, 8, 10, 12, 16 inferior drivers, if they are properly used work better than one good one as they perform “balance loading” sharing the duty across multiple motor and cones. Sure, the increase the radiation surface cause other problems, like beaming and few other but to a degree it is possible to deal with it.

Also, with Accuton-like suspension I do not think that the problem with the softness of suspension but rather with differences of sound prorogation across the suspension and across the cone. In those stupid Accuton-like drivers the cone and the suspension do not know about each other and live by own separate lives, the result is predicable and very auditable.

Still, I feel that the biggest problem of high efficiency direct radiators is not in their intrinsic problems to implement them (those problems do exists) but rather in absence of industry needs in high efficiency direct radiators. You complain that the high-efficiency direct radiators compress but the industry compress sources to much higher degree that high-efficiency direct radiators would. Let be honest: your or my interest and agenda are not smothering the writes user requirements for the driver’s producers and designers. Ad if you look at the today driver’s producers and designers then you would see that for them much cheaper to make an amp a few hundred watts more then to make a driver a few dB more in sensitively. Considering that the majority partisans involved in the audio industry are Morons they o not know any different between high wattage of amplification and high loudspeakers efficiency… Rgs, Romy the Cat

|

|

|

|

Posted by Markus on

01-05-2009

|

|

fiogf49gjkf0d I have recently been thinking about efficiency. Apart from enabling you to use low power amps, is there really any reason why high efficiency is better than low or medium efficiency, all else being equal (and I know perfectly well it never is, but let's assume it is for this thought experiment)?

It occurred to me that historically, the advantage of high efficiency drivers was that they tended to be optimized for low mechanical loss. Low mechanical loss tends to make the sound cleaner, more detailed and more "free" than from drivers with high mechanical loss, a chassis designer told me. It is now possible to buy normal efficiency drivers with low mechanical loss. So, is there a reason to put up with the demands of hi-eff drivers anymore?

|

|

|

|

Posted by drdna on

01-05-2009

|

|

fiogf49gjkf0d  Markus wrote: Markus wrote: | | I have recently been thinking about efficiency. Apart from enabling you to use low power amps, is there really any reason why high efficiency is better than low or medium efficiency, all else being equal? |

|

Fundamentally, all audio is the creation of a sound of a certian loudness level. The different elements used to achieve this should be balanced to minimize distortion and balance the other issues that arize inherent with each type of element.

The low loss low efficiency direct radiator changes one variable about one element in this chain, but it is not the only reason that we would choose direct radiators versus other solutions. For example, keep in mind that by using horn loaded drivers, we reduce the impact of the amplifier's problems on the entire amplification system, since more amplification is achieved by the acoustic coupling of the horn.

etc.

Adrian

|

|

|

|

Posted by Paul S on

01-05-2009

|

|

fiogf49gjkf0d At this point I think that the main advantage of efficient speakers is that they represent the best chance for a sort linearity that to my knowledge can't be gotten any other way. It seems like inefficient drivers simply do not sound the same as the power requirements vary, even if the amp can deliver the power according to test bench criteria. Amp problem or speaker problem, the problem is ubiquitous.

Yes, "HE" dynamic speakers have built-in efficiency/linearity problems, but they are none-the-less easier to work with, to get to a certain point, IMO, versus horns, which are certainly not the easiest roaute to high fidelity.

Yes, horns have some theoretical advantages, and also some practical advantages. OTOH, the main problems with compression drivers with horns are the compression drivers and the horns, not to mention getting them to work well together. It must be difficult to get the things so they don't sound like exactly what they are; at least, I suppose it is because it's difficult that I've never heard non-horny horns. And I always figured horn lovers just accepted the horn sound and tonal weirdness to get the better dynamics.

Meanwhile, it does look like I will have to add another "way" and some more dynamic drivers to my speakers to move in the direction I want to go now.

But first, the BEP...

Best regards,

Paul S

|

|

|

|

Posted by Romy the Cat on

01-06-2009

|

|

fiogf49gjkf0d  Markus wrote: Markus wrote: | | I have recently been thinking about efficiency. Apart from enabling you to use low power amps, is there really any reason why high efficiency is better than low or medium efficiency, all else being equal (and I know perfectly well it never is, but let's assume it is for this thought experiment)?

It occurred to me that historically, the advantage of high efficiency drivers was that they tended to be optimized for low mechanical loss. Low mechanical loss tends to make the sound cleaner, more detailed and more "free" than from drivers with high mechanical loss, a chassis designer told me. It is now possible to buy normal efficiency drivers with low mechanical loss. So, is there a reason to put up with the demands of hi-eff drivers anymore? |

|

Actually if I have time I would probably write up MS Word’s 4-5 pages long of articles with arguments WHY high efficiency is conceptually better and why any extra dB is juts at opportunity. The way to get and the way to use high efficiency is another subject but with all things being equal higher efficiency is better. It is a bit unpleasant that high-fight industry (here I come again!) did not advance the subject and education of public about high sensitivity because they do not do high sensitivity. The industry deployed to public bogus theory about relationship between efficiency and power of amplification and everyone feels settled.

Do not be mistaken – the high efficiency itself is not a cure-all solution and it does not resolve all problems -rather creates them. Still, there are so much “new” this that is “possible” at high efficiency! Regardless the design of your car a high octane gas will prose better drive, will it?

The Cat

|

|

|

|

Posted by jessie.dazzle on

01-14-2009

|

|

fiogf49gjkf0d Why no amount of watts will compensate for direct-radiation :

Start with the obvious : When compared to either multiple direct-radiating drivers or a single horn-loaded driver, to achieve the same SPL, a single direct-radiating driver must work harder; its membrane must move more, its "stroke" must be longer.

If the membrane of the single direct-radiating driver is to keep time with the music, it follows that the speed with which it moves through this extended stroke must be greater than that of the relatively short-stroke multiple direct-radiator or horn-loaded driver.

Due to this greater distance, and need to keep time with the music, the moving mass must be driven at a greater speed. As stroke increases, this speed goes up fast; with speed comes inertia. The materials are suddenly being physically solicited beyond their limits, so they are reinforced and mass again rises.

In the end something must go, and the natural result is that the smaller movements (smaller currents through the coil) just get overrun. Even with a very powerful motor, a membrane driven under such conditions simply does not have time to reproduce the smaller movements.

Ways around this issue : Get SPL via increased membrane surface area (multiple direct radiators), or horns.

Tone :

I suspect that some of what we call tone comes from what is in fact a natural resonance set up by the light-weight, stiff membrane material and its lightness as "seen" by the magnet and coil. Micro-managing a reinforced membrane with increased force is not the same thing.

jd*

|

|

|

|

Posted by Paul S on

01-15-2009

|

|

fiogf49gjkf0d No love lost for any particular driver type here. They are all all-but-hopeless, as far as I'm concerned, just for different reasons.

Jesse, what I wonder is how the small daiphragm of the compression driver, with its very small movements, can be expected to move large quantities of air using low power. Obviously, the preferred "solution" is to couple the diaphragm to the air via a horn. But doesn't this wind up introducing another very subtantial set of problems that begin, in effect, to offset the advantage the compression driver started out with? Especially as frequencies drop?

Anyway, whatever it is that allows some direct radiators to have "tone" (incl. harmonics) that is (are) +/- readily accessable, it winds up being a factor in choosing how to go about setting up a speaker system.

Of course X-max is relative, and there are still a few small-ish excursion direct radiators that were not conceived as the "perfect piston". For that matter, I think it is probably better when compression drivers stay clear of this as a central design criterion, as well.

Basically, it's all about trade-offs, no matter which way one starts off.

By the way, it's been quite a while now... How's "it" coming along?

Best regards,

Paul S

|

|

|

|

Posted by Markus on

01-15-2009

|

|

fiogf49gjkf0d  jessie.dazzle wrote: jessie.dazzle wrote: | Why no amount of watts will compensate for direct-radiation :

Start with the obvious : When compared to either multiple direct-radiating drivers or a single horn-loaded driver, to achieve the same SPL, a single direct-radiating driver must work harder; its membrane must move more, its "stroke" must be longer.

If the membrane of the single direct-radiating driver is to keep time with the music, it follows that the speed with which it moves through this extended stroke must be greater than that of the relatively short-stroke multiple direct-radiator or horn-loaded driver.

Due to this greater distance, and need to keep time with the music, the moving mass must be driven at a greater speed. As stroke increases, this speed goes up fast; with speed comes inertia. The materials are suddenly being physically solicited beyond their limits, so they are reinforced and mass again rises.

In the end something must go, and the natural result is that the smaller movements (smaller currents through the coil) just get overrun. Even with a very powerful motor, a membrane driven under such conditions simply does not have time to reproduce the smaller movements.

Ways around this issue : Get SPL via increased membrane surface area (multiple direct radiators), or horns. |

|

Possibly true, but what's it got to do with efficiency? A normal efficieny driver can be horn loaded just like a hi-eff one.

And isn't our host here on record saying that horns are not about increasing efficiency but about equalisation?

|

|