|

Posted by HifiOrDie on

01-22-2021

|

First off, let me say Hello to all fellow Audiophiles!

I'm an audio-obsessed 29 year old currently living in the United States (Minnesota), and have spent years perfecting HIFI systems in vehicles, and over the past few years have gravitated towards DIY home audio after owning many, many Magnepan Models, Anthony Gallo Acoustics, etc etc, and even built my own Wilson Alexx clones using Satori drivers, after losing my Dad suddenly to cancer and wanting to keep myself pre-occupied in my free time.

I've spent years perfecting my knowledge and skill into turning any vehicle into a HIFI orgasm, usually by Fiberglassing a Midrange and Tweeter into each A-Pillar (vertical section on outsides of windshield), a Midbass into each door or most preferably the Kick Panels, and a Subwoofer (or two) preferably mounted Infinite Baffle (trunk baffle), with 7 channels of ampification, and absolutely MOST importantly in a vehicle - The DSP - as Time delay, Output level control, EQing, Phase, and Crossover control is an ABSOLUTE MUST in a vehicle if you want a mindblowing result, correct soundstage and imaging, correct balance/response, etc.

Home audio is obviously quite different. What brings me here today, is I have become obsessed with the want and need to build my own 3 way horn design for fun and enjoyment, ever since attending Axpona and hearing the absolutely gorgeous and fantastic sounding Sadurni Acoustics. Jorge is an awesome guy and has been very helpful with any questions i've asked, and actually pointed me to this forum.

So i've tried to search a bunch before asking for help, but i'm having a little trouble so I figured i'd throw some questions out in case anyone is willing to save me some time as I admittedly know far less about horn design, or even just point me in the right direction to find my own answers. I can't seem to find a way to determine what Horn Profile I need to do for the Midrange and Midbass. I gave HornResp a shot, but after entering as many driver parameters as available, I was then admittedly lost, Lol.

Upper Midbass Horn:

- I'm thinking of using a pair of Satori MW16P 6.5" as the midbass drivers as long as there aren't any glaring reasons not to.

- I read in Romy's post that for midbass, as long as the horn is some kind of exponential curve, it should be just fine, so now i'm just left wondering what kind of result can I expect with up to a 25" Mouth (WAF, size of room, etc), and around 4" Throat. It's my understanding that the Throat size and Mouth Size determine a High Pass Filter of sorts? Please correct me if i'm wrong, but it seems as if the size of the mouth determines how low I can expect the midbass to play - and that the driver should be capable of one octave below that point (FS one octave below?).

Turbine/Horn Midrange:

- I've been trying to find a good midrange driver that doesn't obliterate the wallet, as I've spent thousands on high end drivers - so I was hoping to find something more budget friendly yet still a fantastic driver without dropping a grand on a pair haha. Any recommendations would be highly appreciated!

- As far as the horn profile for the midrange, I was curious how to go about figuring that out as well. I'm guessing if I do a 1" driver, the Throat should match up to that exactly, so that leaves me with just the Mouth diameter.

Horn Tweeter:

- I can figure out after everything else is good it seems, and if I need one (would like one especially for aesthetics and especially if response dictates the need), but I was thinking either a Horn, Compression or Ribbon driver, though it does seem to make more sense to keep it in the compression family

- Any recommendations would be highly appreciated!

Thankyou to anyone able or willing to help me on my first Horn Journey! I have all of the tools to get it all done, aside from a lathe or CNC, so i'll get that figured out unless anyone knows someone willing to ship in the US or near Minnesota  (a man can only hope). Thankyou again and have a good one! I'll keep searching and learning in the mean time! (a man can only hope). Thankyou again and have a good one! I'll keep searching and learning in the mean time!

|

|

|

|

Posted by Paul S on

01-22-2021

|

Welcome. Things have been quiet around here since Romy got preoccupied with his family, but don't let that stop you from doing a lot of reading. If you are a persistent reader who takes notes you can save lots of time and money vs. trial and error building horns, that's for sure.

Best regards,

Paul S

|

|

|

|

Posted by HifiOrDie on

01-22-2021

|

|

Bummer! Alright well I definitely will keep up the consumption of knowledge and take notes! Thanks for the reply, Paul!

|

|

|

|

Posted by Romy the Cat on

01-23-2021

|

|

Hello, 29-year-old, audio enthusiasts. I'm still alive and

although I am struggling to manage my life between three small kids and a lot

of heavy work, I still man you told my site attentively. I will be happy to

collaborate with you on anything you need, although I didn't exactly understand

when you were asking about.

I would like, however bring slightly different aspect that you might not have

respective at this point. I think those wonderful hi-fi sensations that you are

trying to get in the way treated by many other people as self-contained and

very much self-serving objective of audio. It is very pleasurable and

commendable objective, so the solo orgasm. The idea of togetherness censual explanation have on benefits and the most important not locked strictly in

sexual pleasure but has a lot of open communication portals to spiritual,

emotional, intellectual, psychological and many other dimensions of

human consciousness. so my major and non-specific recommendation in this point

is do not chase Hi-Fi solutions but rather chase a complete package of

interaction with reality where Hi-Fi would be a very organic component but at

the same time would be balanced out with other priorities of your life. I

understand that those lectures it is not with that you would like to hear, you

would rather to hear what driver to buy and what capacitor to use but from a perspective

that I see it now you would not be able properly perceive that beauty of a

given capacitor without connecting to anything else. Many people trying build

an audio just as audio but I feel it is not necessary mistakes from

behavioral perspective but rather a mistake from methodological perspective. If

your objective to build a playback is to "to get zapped"

then you might use slightly different design principles in order not to

get from playback faulty expressions but rather a philosophical honesty. After

all not everybody consider Horovitz as a great pianist..>>

|

|

|

|

Posted by rowuk on

01-23-2021

|

You will find a very basic motto or life theme here that keeps recurring:Random efforts produce random results!In relation to audio, this means that buying somebody elses best of everything does not lead to a personal superior result.

Basically processes replace randomness. I am not sure that the direction of building car hifi for eargasms is a noble direction. If I think about music in my life (I am a professional trumpeter), the live experience needs emotional tension and relief - programs that only have popular film music, are spectacular - but only for a while.

Coming from car stereo, the first "problem" that you will have will be bass. Car audio puts our ears in the speaker cabinet - the most unnatural place to be.

I am convinced that the path to a great horn system is a building process over years. As we learn about what horns do and don't do, we develop needs to leverage in our system. I might be so bold as to recommend starting like many readers here with a 12" or 15" in a large sealed box and using a horn from 700Hz (just as an example - depending on the horn, 500 or 1000Hz may be better). Get those to sound properly and then think about implementing a second horn from 100 to 1000 or so as a SECOND step. This fundamentals horn from 100 to 1K is probably the most critical in the system. Spend another year with that and learn about tone and that you can be perfectly happy with speakers without considerable extension at the bottom or top. Once you are perfectly happy, you can search for a LF and HF solution that integrates with the sound of the rest of the system. Go to as many live concerts - especially with non amplified instruments and learn about bass, imaging (I call it geometry and space not imaging) and "air" - all things dramatically distorted in cars or most home systems. Determine what music is good for references - for the fundamental channel, I use for instance a recording "The Schöne Müllerin" with Dietrich Fischer-Dieskau. The voice and piano are very naturally recorded and would show any warts in the fundamental channel.

Good luck. This site is Romys personal diary how he built his system. It is much more than a blueprint for what to buy and how to solder it together. The playback section is a good reference.

|

|

|

|

Posted by HifiOrDie on

01-24-2021

|

Well that really is damn frustrating and admittedly very aggravating. After typing a rather lengthy and enthusiastic response, I somehow lost everything before posting and it couldn't be recovered. So we'll attempt to try this again, though admittedly, likely short-changing myself on this one.

Anyways!

I'll again start by saying thankyou to both of you guys for taking the time to reply! It is well appreciated!

- I agree that the best way to get a feel for how live music should truly sound, is to attend as many live concerts/shows/events - especially unamplified. I will also say though, that a lot of times we just want our systems to sound enjoyable.

- I also agree that it's not always advisable to tell someone when and what driver to use, as results may vary. Personally, I'm more so under the opinion that general help is usually best.

For instance - when looking for HiFi compression mids and tweets, I see that a lot are categorized as "Pro drivers" rather than HiFi orientated. I'm under the assumption that these drivers will typically sound like ass, as they're designed for rigidity and SPL, rather than High Fidelity sound quality.

Would my assumptions be correct, or am I completely off? Are there only expensive options that will sound good like Altec, Fostex, JBL, etc?

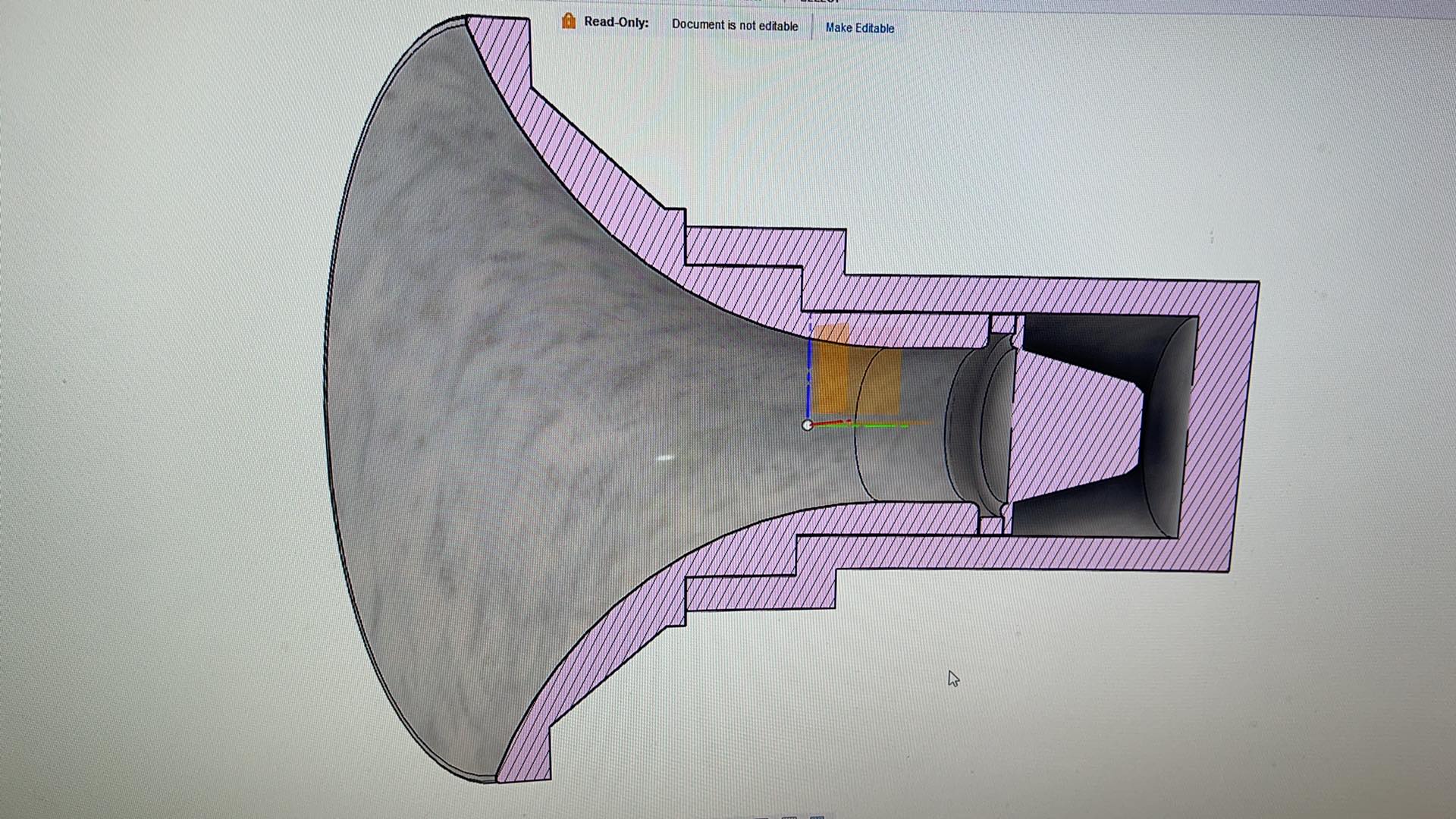

- I've also been having a LOT of fun using CAD software (Fusion 360), designing then 3D printing different Horn setups and enclosures for my Computer Desktop, but using regular dynamic drivers - with FANTASTIC results. I was absolutely mind blown at the pinpoint holographic sound stage and imaging.

I'm currently about to print a 25" Tractrix Horn in 3 parts as I have 3 large 3D printers, and I'll attempt to load the inside with either Lead Balls, Sand, Plaster, or something similar to add as much weight as possible - then JB weld them back together. Hopefully I'm successful as it will give all of us a whole other option for those like me who at the moment can't find someone in the US with a lathe big enough to carve out my Horns. I'll keep everyone updated on that progress.

Last but not least, I did find a "Tractrix calculator" that says the best I can get at 25" diameter (Horn Mouth) is 160hz, does that sound about right? If that's the case i'll either try to go bigger without looking ridiculous, or work out a subwoofer setup that can satisfy up to that range.

|

|

|

|

Posted by rowuk on

01-24-2021

|

You really should read the entire thread on Romys Macondo before building anything. Horns are usually not very forgiving about using the bottom octave of response. Romy addresses this in his usual depth.

I am using FAITAL HF146 drivers on 250Hz horns from about 450 Hz with very satisfying results. They work down to around 300 Hz without "problems", the horn just gets too honky below 450Hz.

Finding people with lathes is no big deal.

|

|

|

|

Posted by Paul S on

01-24-2021

|

There is so much material worth reading here that it would be hard to list it, and not all the important material is where one might presuppose to find it. Romy hinted at this when he suggested, broadly, that you take a "wholistic" approach. There is a horn thread started by a Russian guy who spent a fortune in a New York Minute trying as quickly as possible everything he read or heard about horns before dumping all of it and going into something else. This thread might be called a "Cautionary Tale", one of several here at GSC. Believe me, you simply will not get all this figured out and concluded in a year, or anything like a year, at least if you DIY a horn-based system, especially if it includes big horns. It's not likely, but it's possible you could get lucky and find and buy pre-made stuff that is "good enough" for you in less than a year. One "problem" with hi-fi is, the "more you know", the more you want from your system.

Best regards,

Paul S

|

|

|

|

Posted by HifiOrDie on

01-24-2021

|

Completely understandable. That's why it's fun! It's enjoyable to make something, study the results, make changes, and start over! That seems to definitely be the theme with horns from what you guys are telling me.

So it sounds like I shouldn't expect perfect results right from the jump, which was always to be expected since my assumption is that calculator's can only predict so much at the end of the day. I can see how this would become an expensive endeavor, especially considering the $600 quote for two 25" Tractrix Horns made from Soft Maple that I was just given.

So out of curiousity, what are your guys' thoughts?

I found a guy that is willing to turn a couple Tractrix Horns for me, but there's a few caveat's...

1) He's apparently highly experienced with the Lathe, and has a really nice one. But he's never done Horns before, so I gave him an introduction to the process from what I've seen others doing, and after a few misunderstandings of a good process, I think i've finally gotten him to catch on to how it's done.

I even said that I would bring over the stack of glued together rings, with the inside diameter already cut out (except for the throat end I was planning on leaving one or two rings closed off so it could be attached to the lathe), so it would be much less of a headache and time consumption for him, but it seems he wants to do the stacking himself (which unfortunately will add to the cost), but not the end of the world.

So that's one slight concern

2) He seems to really, really not want to use MDF... and use Soft Maple instead. Not sure if this would be a problem or not, but i'll do some research.

3) All said and done, he says he'll do it for about $600. How does this sound for a price in your guys' opinions? Doing about a 25" or so diameter

Again, thanks a million!

|

|

|

|

Posted by mats on

01-25-2021

|

...is a most admirable quality. As an elder who has found the quarantine couch

exceedingly pleasing, I honor your enthusiasm. However, much can be said for the

wisdom of studying eluded to in the above responses.

So, in your large horn you do not need a tractrix curve. It will be a waste of

precious vertical commodity. To the best of my understanding, an exponential

horn will suffice, and that the tractrix can be saved for the 400Hz and above range.

LeCleach flare may be significant at even higher frequencies.

I have found much pleasure in learning to implement a midrange horn, mostly with

Alnico drivers using phenolic diaphragms. They tend to err on the forgiving side,

making learning pleasant.

-Mats

|

|

|

|

Posted by Romy the Cat on

01-25-2021

|

ifiOrDie,

regarding the material of the horn. There is in my view no matter the

logically clean empirical data that material of horn matters. Certainly would

have differences out between a horn made from aluminum foil and hard made from

cotton. However the conversations elevating Siberian oak over Canadian oak or

one quarter MDF versus half inch in MDF are not serious. Horns are finishing a

different way which probably more impact sound than the material itself

particularly for mid-range horns. There are some anecdotal evidences then

Philippians makers for instance use not dried enough food which has a tendency

to change geometry this time. How much it has practical impact is hard to say.

Mostly people are in a certain camps of beliefs and they advocate the pass that

they took. I am quite comfortable with my pass however completely different

things make me excited. What make me excited in the horns is to see when people

do something absolutely wrong and absolutely country is that everything that I

know and still get great results. So if you willing to make horns from flatten

out Coca-Cola cans then please send me a picture it would be fun. Regarding

celeste, I don't think that I can be useful to you. It is a website diyaydio is

that cost a lot of community of people who build horns and collaborate about

prevailing practices and sometimes about results. You might try to ask there.

Even though, the majority of folks there shooting blind into a moving Target

but sometimes you can catch a good fish even in mirky water.

|

|

|

|

Posted by anthony on

01-25-2021

|

HifiOrDie, I've turned my own horns from MDF and the end-grain is a real bitch to finish properly. You have the outside of each sheet and the glue in between which is nice and hard and then softer material in between, sort of like tiger or zebra stripes or hard/soft/hard/soft et cetera. The end-grain takes a lot of sealing properly if you do not want problems years down the track and of course if you sand it too much then the hard bits stay high and the soft bits get low. But it is cheap to buy and easy to cut on a lathe.

I've not turned horns of anything but MDF on the lathe but other hardwood things have been a doddle to finish properly...not saying that soft Maple is great, but there is probably less work finishing and painting the horns than with MDF.

See below a photo of the front half of one of my Upperbass horns on the lathe...you can see the tiger stripes of hard/soft/hard. That horn is 1m diameter and weighs 85kgs and used 3 litres of primer for the first six coats. Then I sanded it back smooth, or relatively so, and have now applied another six coats of primer which I will sand back to see what I have got.

.JPG)

Anyway, that is probably one reason why your guy does not want to use MDF.

|

|

|

|

Posted by HifiOrDie on

01-27-2021

|

Damn.... Those are a beautiful site to behold!

- How long does it take to turn a pair of those once all the rings are glued together?

- Got any more pics of the process or after results?

- Just out of pure curiousity, how much cash flow would it take to get you to build another set?

- What kind of lathe did you use? (specs)

I'm seriously considering buying a damn lathe..... lmao

|

|

|

|

Posted by anthony on

01-27-2021

|

For a large horn like this you can't glue all the rings together and start turning because the imbalance wil shake things to bits plus you have to account for where the cutting tool can safely and physically reach. So the process is to glue a few rings together...next day once the glue is dry turn those rings then glue the next group on...come back the next day and turn those rings and glue the next batch on and so on. Maybe a couple of hours work a day spread over quite some time for the big horns.

A pair of smaller horns like the 400Hz can be cut/glued/turned/sanded/undercoated in a weekend, say 20 hours of work. Larger 250Hz horns might take 4 days to get undercoat on a pair, so 40 hours. The 100Hz horns of which you only see the front half of one horn in that photo take maybe 150-200hrs to get to undercoat stage, but that work is spread over a couple of months the way I do things.

Just a 'normal' lathe but I built my own back-tables for it and cutting tools.

No amount of money would get me to turn horns for someone else...I kinda wish I'd got someone else to do mine for me because despite best intentions finding time for this has proved a major issue.

|

|

|

|

Posted by Jorge on

02-03-2021

|

HI "Hifiordie" I want to tell the readers here that this guy is seriuos and has some serious talent.Unluckily for him he has been bitten by the same insect that got us and is obsessed by horns, please do listen to Romy and try to balance your life before going too crazy. Now crazy is good!

The guy wants to glue the parts himself so he can turn them partially, like Anthony is describing but you do have to be careful in one thing: Bass horns do need to be massive, weight matters and materials matter, I have made several horns now, from 110 hz to 140 hz and all the way up, from MDF to HDF (very heavy) to Plywood and now walnut and maple for midrange horns. Don´t make horns too thin, keep them at least 1 1/2" thick. I am afraid you will end up with too thin maple horns and that would defeat the purpose.

Yes MDF is a mess to finish, it´s like polishing a turd... Your idea of 3D printing I think is fascinating, if you can fill them up with sand maybe that is best. NO finish needed.

160 hz is good enough for a start, as Romy claims here: The most important part is the Upper bass horn and the midrange horn combination. Give a close reading to Problems with horns Upper bass horn and How to select mid-upper bass horn drivers from the Audio Knowledge tree.

And no, pro drivers are not crap, JBL, Altec and almost all of them started as PRO drivers and imho have been surpassed by the new technologies and newer PRO drivers, so feel free to take a pick, but look very closely to the published specs.

|

|

|

|

Posted by anthony on

02-03-2021

|

|

Jorge, I remember the first time I put my hand on a 120Hz fibreglass horn with music playing and the vibrations were staggering...the horn was it's own musical instrument, making its own sounds for sure. The smaller horns were less of an issue but at that stage my instant decision was to make mine very heavy with a lot of wood and a shape that tends towards inertness. My big 100Hz horns are not yet in service (still to be painted) but the 250Hz and 400Hz horns are completely inert during the loudest of playback, at least as inert as my sense of feeling is able to discern.

|

|

|

|

Posted by HifiOrDie on

02-03-2021

|

Thanks for the replies again everyone!

Ive made some good progress on 3D printing a set of horns!

Just a general guideline for anyone curious, with the 20" Diameter and 10% Infill (percentage of filling structure), It takes about $45 of PLA plastic, and 4 days to print each Horn - printed in 3 sections one at a time

https://ibb.co/4Y17F9J https://ibb.co/gvLQmZ1 https://ibb.co/YdJszSV

|

|

|

|

Posted by HifiOrDie on

02-03-2021

|

Posting a picture seems to be harder than I would’ve imagined... I’ll try again later

|

|

|

|

Posted by anthony on

02-04-2021

|

Picture 1

Picture 2

Picture 3

You can also upload the images directly to the site (better)

Looks interesting...

|

|

|

|

Posted by HifiOrDie on

02-04-2021

|

anthony wrote: anthony wrote: | |

Thanks bud! I'll try again

|

|

|

|

Posted by HifiOrDie on

02-17-2021

|

So i've made some more progress. Now it's time to select a Midrange and Tweeter!

Anyways...... About $200 in PLA Plastic LOL, $75 in quick-cement, and 312 hours worth of printing between 3 printers... I present:

|

|