|

Posted by cv on

09-23-2009

|

|

fiogf49gjkf0d Hi Romy,

Prosaic question - what's the part number for these? Finally building some LF arrays and need a good few reasonably priced good sounding posts... sounds like these will fit the bill.

Many thanks,

cv

|

|

|

|

Posted by Romy the Cat on

09-23-2009

|

|

fiogf49gjkf0d

… besides the “Superior Electric” but you can’t buy it anywhere beside the Allied Electric. I have no idea why others do not see them.

cv wrote: cv wrote: | | Prosaic question - what's the part number for these? Finally building some LF arrays and need a good few reasonably priced good sounding posts... sounds like these will fit the bill. |

|

You might find them in Allied catalog at

http://www.alliedelec.com/catalog/pf.aspx?FN=434.pdf

Look at the middle of the page, all those BP30s are good. Years back, when I build ridicules external crossover for AG Trio I have done very thorough investigation into the sound of the binding posts. I know, it sounds stupid but I did buy all of them and I did listen all of them – I still have that shoe box with all imaginable binding posts. It was a strange conclusion: the more the binding posts looks and feel “hi-endish” then more horrible it sounds. The worst of them were the most expensive large WBT posts. The Superior Electric were hand and shoulder better then anything I have tried.

What I concluded that it is not the Superior Electric posts themselves are the key but the design type. Most of the Hi-Fi company tries to make the post to look impressive making it “large”. That excessive amount of metals in the connection fucks up sound very much, making bass hollow. What is important is to have a binding post that would not introduce too much gauge difference in connection area relative to the rest of your cable.

The Superior Electric post do not look very impressive, in fact the look very cheap but they are have absolutely no competition in term of sound quality. Thai is perhaps you would never see them in high-end equipment. The Cat

|

|

|

|

Posted by cv on

09-23-2009

|

|

fiogf49gjkf0d Much appreciated Romy. Extremely valuable research this - the last thing I want to do is spend a fortune on high end jewelry BS.

Guess it will be gold or nickel plated (the gold probably sits on a layer of nickel anyway). I'll also see what matching plugs the might have.

Thanks much,

cv

|

|

|

|

|

|

|

Posted by Romy the Cat on

09-24-2009

|

|

fiogf49gjkf0d I do not like on Connex that I cannot use tools to tight the post hard. With my kind of cables and the spades that they use the force of my fingers is not enough to tight the binding posts. BTW, there are some people who feel that the force of binding posts tightening affect sound, I am not one of them. I am surprised that the Morons do not yet produce and advertise some kind of tightening tool with torque range calibrated in musicals styles…

The Cat

|

|

|

|

Posted by Paul S on

09-24-2009

|

|

fiogf49gjkf0d Trying to tighten "cheap" binding posts can be frustrating, indeed.

I get the things as tight as I can with the cable spade "not quite" dialed to the point where I want it to wind up (in terms of the angle at which the cable departs the amp/component), and then I use the cable spade itself as leverage to get the post tight. In other words, I hold and turn both the cable spade and the post at the same time at the end of the tightening cycle.

I always habitually get spade lugs in there very tightly; but I was freaked out to notice changes in sound with WBT NextGen and similar-type IC connectors (with the threaded outer "sleeves") according to how tight they are. In all situations I have tried, there has been an "optimum" tightness of the outer sleeve. Odd that I have always just gotten the spade lugs as tight as I reasonably could...

BTW, I do not trust amp/speaker connections to "bananna" plugs. I want those suckers tight.

Paul S

|

|

|

|

Posted by cv on

09-25-2009

|

|

fiogf49gjkf0d Hi Paul,

Completely agreed - I clumsily said plugs, when I meant spades - was simultaneously looking at some proper lemo plugs for signal and got confused.... Bananas, esp. for big hog woofers are - well - exactly that.

I've also used the technique you mention, but may be using more fragile foil cables, so will be ordering the type with the nut as opposed to knob type fixing. It's a shame cos over here RS only stocks the latter. Farnell have the ones I want but far more pricey. Ah well.

A friend over here has the silver WBTs... I pointed out to him that for what they cost, he could have bought a pair of woofers... which come with their own binding posts...

Best,

cv

|

|

|

|

Posted by jessie.dazzle on

09-26-2009

|

|

fiogf49gjkf0d Romy wrote :

"...With my kind of cables and the spades that they use the force of my fingers is not enough to tight the binding posts..."

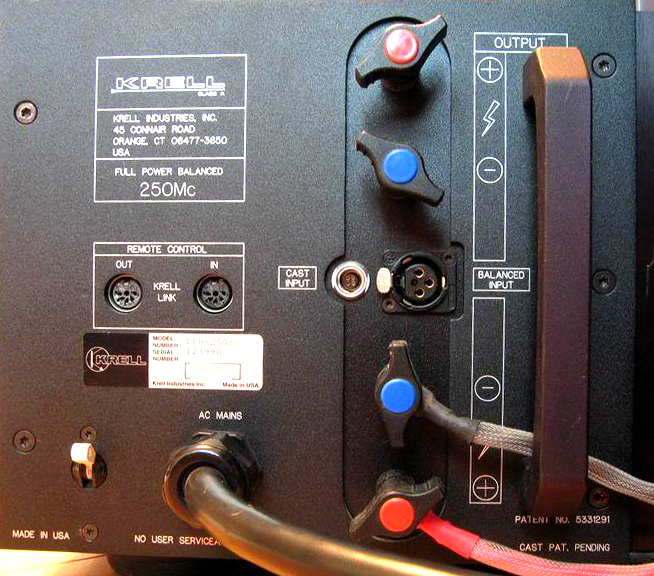

It would be nice if Superior would issue a design that used the same metal parts as their existing posts, but had nice big plastic wing nuts like some of the old Krell amps used to have. This would of course require that the plastic wing nut be attached by some other means than is currently the practice; they are simply pressed over shallow splines in the metal part that turns. This is why using a wrench on the Superior's current posts is not a good idea.

I too use "The Paul Technique", which turns the fundamental problem with most binding posts (rotational forces are not isolated from clamping forces) to our "advantage". The designs that use washers under the nut do not (with very few exceptions) entirely isolate rotational forces from clamping forces.

The best temporary connection is stranded bare wire that has been properly clamped... The bare part of the wire should be gold plated to prevent oxidation. I wish such an option were a standard offering among cable manufacturers.

Then, to properly clamp that wire, we would need a good split-bolt connector.

Below is such a connector... Yes its sort of crude, but the same concept could be refined for audio (don't forget the wing nut!). This design isolates rotational forces from clamping forces, while properly confining the strands of wire.

jd*

|

|

|

|

Posted by Romy the Cat on

09-26-2009

|

|

fiogf49gjkf0d

The BP30-2 post has hex head. You might get any hex wrench and it is no problem anymore. I found that that the Audioquest wrench is VERY comfortable as my posts are flimsy for my cables (Dominus is VERY heavy) and I shall not apply overly high torque. The Audioquest wrench is very nice as after a few posts that you destroy you learn how much stupid torque you might apply.

http://www.musicdirect.com/product/72740

Make sure you have two – green and red for right and for lest channels ....

I remember I was keep losing the wrench, the Koshka always love to play with it footballing in all imaginary places. Then I attached to them a magnet and just magnet the wrench to the amps back. I heard that if I do not use a regular magnet but a field coil then it will be able to find it twice faster on the back of the amp….

I know for some it is not a big deal but wait until you need to connect 24 cables (My Dominus are dial mono) in a specific order while you are in a very not comfy position bent over the amps…. A good wrench is a certainly is very good help. The caT

|

|

|

|

Posted by Paul S on

09-26-2009

|

|

fiogf49gjkf0d Over time I have observed that, in most cases, one quickly turns the corner from "enough' connector mass to suddenly arrive at "too much" connector mass. I started out with a cable clamp like Jessie shows for my 6 gauge "dedicated ground" wire for just the reasons Jessie cites, that it needs to be REALLY TIGHT. From that point, I actually wound up soldering that whole effing junction to "protect" it/keep it from "going bad".

Warning: The following is for total OCD nutbags only:

I always clean my solder joints mechanically; then I "pacify" them with alkaline flux buster; then I coat the joints with a couple of applications of very saturated "natural" shellac.

In other words, I crimp down key permanent connections, then I solder them (with high copper content solder...), then I keep the air off the joints.

I have already shared the dielectric grease "secret" for "normal" "mechanical" connections, including (so far, so good...) tube pin connections.

I used to use Caig Pro Gold on my amp/speaker connections; but now I use di-electric grease on all 'temporary" "mechanical" connections' (6 months , and all is well...).

not to bust any DIY bubbles, but the fact is that most "soldered" joints are also - effectively - "mechanical" connections, very similar to the vicious copper lug Jessie shared, and not always that good electrically, FWIW.

Not to make work for those commited to easier "solutions", but I settled on my "system" by listening and I "backed it up" with measurements, apropos

Caveat: If ignorance is bliss, STAY AWAY from volt meters! Do NOT experiment with signal/noise/loss readings across various connections!

Paul S

|

|

|

|

Posted by mjloudspeaker on

09-27-2009

|

|

fiogf49gjkf0d  Paul S wrote: Paul S wrote: | Over time I have observed that, in most cases, one quickly turns the corner from "enough' connector mass to suddenly arrive at "too much" connector mass. I started out with a cable clamp like Jessie shows for my 6 gauge "dedicated ground" wire for just the reasons Jessie cites, that it needs to be REALLY TIGHT. From that point, I actually wound up soldering that whole effing junction to "protect" it/keep it from "going bad".

Warning: The following is for total OCD nutbags only:

I always clean my solder joints mechanically; then I "pacify" them with alkaline flux buster; then I coat the joints with a couple of applications of very saturated "natural" shellac.

In other words, I crimp down key permanent connections, then I solder them (with high copper content solder...), then I keep the air off the joints.

I have already shared the dielectric grease "secret" for "normal" "mechanical" connections, including (so far, so good...) tube pin connections.

I used to use Caig Pro Gold on my amp/speaker connections; but now I use di-electric grease on all 'temporary" "mechanical" connections' (6 months , and all is well...).

not to bust any DIY bubbles, but the fact is that most "soldered" joints are also - effectively - "mechanical" connections, very similar to the vicious copper lug Jessie shared, and not always that good electrically, FWIW.

Not to make work for those commited to easier "solutions", but I settled on my "system" by listening and I "backed it up" with measurements, apropos

Caveat: If ignorance is bliss, STAY AWAY from volt meters! Do NOT experiment with signal/noise/loss readings across various connections!

Paul S

|

|

Hi Paul My take on this is simple; what does industry do with these same parameters, as electricity usage (and loss) means big bucks to them. They do not use any of these methods, but instead use practiced and specific standard electrical code standards and means and practices. Why does audio not follow this, why is audio bound to be above standard electrical practices, and why are audio persons bound to skew good and sound electrical practices into other zones of/for sonic reasons? Electricity flows as it does, not as we desire. Can you (or we) hear differently or is this just a personal achievement of a good job of electrical connecting? curious, j.

|

|

|

|

Posted by Paul S on

09-28-2009

|

|

fiogf49gjkf0d 'Standard Practice" most certainly depends on what part of "industry" you are looking at. While an automoble assembly line might adopt one set of standards, submarine SONAR or interstellar spectrometry systems, for example, would most certainly use others.

Clearly, it is exactly the VERY SPECIFIC regulation of "electricity" that determines how those "electrons" present themselves after "processing".

I think zip cord people and other circular thinkers have their own sites.

Paul S

|

|

|

|

Posted by mjloudspeaker on

09-28-2009

|

|

fiogf49gjkf0d  Paul S wrote: Paul S wrote: | 'Standard Practice" most certainly depends on what part of "industry" you are looking at. While an automoble assembly line might adopt one set of standards, submarine SONAR or interstellar spectrometry systems, for example, would most certainly use others.

Clearly, it is exactly the VERY SPECIFIC regulation of "electricity" that determines how those "electrons" present themselves after "processing".

I think zip cord people and other circular thinkers have their own sites.

Paul S

|

|

I have to agree with you on "parts of industry", with specific standards inherent in specialization, but "specific regulation" if inaudible does not matter to me. And the process is to get a coil to move in a magnet. Simple enough, I think. And when is enough enough? That is my only point in this, but a job well done is something else entirely, with or without the advancement of audio sonic results. Which brings to mind this interesting article- by Nilay Patelposted Mar 3rd 2008 at 8:03PM on engadget HD. Audiophiles can't tell the difference between Monster Cable and coat hangers My thoughts here, in no way circular, not subject to change without notice really. "P.S. I wished I owned a zip cord manufacturing plant." Maybe I could buy myself a nice meal, in a fine restaurant, go to a movie, have a few dollars to go shopping, that sort of thing. Take care, j.

|

|

|

|

Posted by Paul S on

09-28-2009

|

|

fiogf49gjkf0d J, I hope you know by now that I really don't care about anything audio but my own results, except that I actually like sharing about this a little. Very specifically, I have absolutely no interest in trying to convince anyone of anything audio.

I did not and will not read the Monster Cable vs.coathanger thread, since it IS circular thinking, after all, on the face of it and at the heart of it's premise.

The best approach to this site, IMO, is not to simply stir things up but rather to read extensively in order to be able to establish a relevant context as a basis for evaluating the information. This, IMO, is one's best shot at productive dialog here.

Best regards,

Paul S

|

|

|

|

Posted by mjloudspeaker on

09-28-2009

|

|

fiogf49gjkf0d  Paul S wrote: Paul S wrote: | J, I hope you know by now that I really don't care about anything audio but my own results, except that I actually like sharing about this a little. Very specifically, I have absolutely no interest in trying to convince anyone of anything audio.

I did not and will not read the Monster Cable vs.coathanger thread, since it IS circular thinking, after all, on the face of it and at the heart of it's premise.

The best approach to this site, IMO, is not to simply stir things up but rather to read extensively in order to be able to establish a relevant context as a basis for evaluating the information. This, IMO, is one's best shot at productive dialog here.

Best regards,

Paul S |

|

Thanks Paul I have extensively read this site, which formed my opinion to contribute to it. I have not to Lynn Olson's, DIY audioforums, as I find it overly analytical and cerebral, I am an emotional person at heart. I care not for mathematical explanations of the musical kind. But what I am saying is that if this is about higher audio and the advancement of it, the very premise of this site, then how do we proceed to do it, for real, and in a relevant way? In my mind, I always come back to this point. I've said it, this is one of the best. But it can go off quite a bit, into it's own little ethereal thing. I enjoy this, understand emotions of it, but sometimes, feel I must step up to the plate and ground it. I now think I may be wrong with this absolutely. Stirring stuff seems the point of this site, with owner/author especially, and I had assumed that I could contribute somewhat, but think this is not really the case anymore. I work and live in a highly competitive workplace environment, and I hold no grudges and will say to you what I mean, without remorse, and my attitude reflects this for sure. I also don't care about audio anymore or less, but really wished my audio ideas were relevant, as my experience goes back quite a bit. I now doubt this, as like you, my path is my own, and audio seems so disfunctional in "togetherness" or even dialog, my excitement for it has possibly gone in my youth. Romy has told me to fit in, now you. Then, not fitting in Lynn Olson's cerebral club, or this feline one, mj should and/or shall vanish, possibly? "I now say probably." And quirky audio ideas can blossom here, unimpeded by logic and reason and listening, with egos intact all around. I am sure, mjhe will not be missed greatly. But they also say, do not kill the messenger. So I apologize, as I am merrily him. Because I am a Romy site fan, not just a contributor, I remain, REspectfully Yours, j.

|

|

|

|

Posted by Paul S on

09-29-2009

|

|

fiogf49gjkf0d

J, I mean no disrespect when I say it is not about you - at all.

It is certainly not my place to instruct, and I am not interested in any aspect of the Monster Cable vs. coathanger (vs' "audiophiles") "controversy".

Best regards,

Paul S

|

|

|

|

Posted by mjloudspeaker on

10-11-2009

|

|

fiogf49gjkf0d  Paul S wrote: Paul S wrote: | |

J, I mean no disrespect when I say it is not about you - at all.

It is certainly not my place to instruct, and I am not interested in any aspect of the Monster Cable vs. coathanger (vs' "audiophiles") "controversy".

Best regards,

Paul S

|

|

The only real interaction I wish with copper is of this kind, regards, j.

|

|

|

|

Posted by N-set on

02-05-2017

|

Paul S wrote: Paul S wrote: | fiogf49gjkf0dOver time I have observed that, in most cases, one quickly turns the corner from "enough' connector mass to suddenly arrive at "too much" connector mass. I started out with a cable clamp like Jessie shows for my 6 gauge "dedicated ground" wire for just the reasons Jessie cites, that it needs to be REALLY TIGHT. From that point, I actually wound up soldering that whole effing junction to "protect" it/keep it from "going bad".

Warning: The following is for total OCD nutbags only:

I always clean my solder joints mechanically; then I "pacify" them with alkaline flux buster; then I coat the joints with a couple of applications of very saturated "natural" shellac.

|

|

Paul, there is something I wanted to ask you but have kept forgetting. When I apply your shellac cover trick,

I noticed that with time (days) the shellac layer over the joint becomes bubbled, not smooth and semi transparent as in the beginning, but

develops millions of frozen bubbles in it. They do not open up so I guess the air protection is still there but.... Is that normal? I use chemically pure isopropyl to dilute shellac into a very thick mix.

Cheers,

Jarek

|

|

|

|

Posted by Paul S on

02-05-2017

|

Jarek, to begin with, I hope it is understood that I was referring to joints that are already soldered, which means they have already been roughed up/burnished, then fluxed (at least in the case of thick wire, "fittings", or plate), and of course there is also acid/flux core in the solder. It's what I do after soldering that that I began with, namely scraping off the detritus that the soldering produces, and then pacifying the scraped, soldered area, and cleaning that with water., then drying it all before applying shellac. I have never tried mixing shellac flakes with isopropyl alcohol, since I was taught to use de-natured alcohol. Whether this is a factor, I do not know, but I have not had the bubbling you describe. Again, one needs to get both the acid (flux) and the alkaline (neutralizer) and any water used for final wiping off the copper/tin before layering on the shellac. I don't know if I mentioned it before, but another "trick" with shellac is to use multiple, thin layers rather than globbing it on.

Best regards,

Paul S

|

|

|

|

Posted by N-set on

02-05-2017

|

Paul, thank you. Sure thing: I first solder, than clean mecanically and/or with a special solution for cleaning PCB's (KONTAKT PCC), let it dry and then apply shellac.

I dont use water after all that. I may also apply to thick a layer. Isopropyl evaporates very quickly so the bubles could be it evaporating from the deeper layers. I'll try the de-naturated alco.

Edit: Doing some chemistry homework, found that isopropyl will evaporate *slower* than ethanol. I was wrong above. So maybe thats the reason-slowly evaporates from the deep, making bubbles.

|

|

|

|

Posted by Paul S on

02-05-2017

|

Yes, try ethanol (with as little water in it as possible). Contact cleaner is typicalyl just that. I have ass-u-me(d) that part of your post-solder cleaning involves something alkaline, as well, to neutralize the solder flux. That's why I also water wipe (then dry) to finish, to get the alkaline residue off. I tend get more build-up on the joints than others because I flux the hell out of thick parts, especially, and this absolutely requires scaling as part of cleaning the joint.

Paul S

|

|

|

|

Posted by Paul S on

02-05-2017

|

Here's one example of what I mean regarding cleaning a solder joint:

https://gokimco.com/chemtronics-es835b-flux-off-rosin-flux-remover.html?gdffi=a2b2595eeb2e44a8bc2e332d298712bc&gdfms=D2663A01824B473FAC1E75660BF93E39&gclid=CLWNztik-tECFUlNfgodZUgKGg

Plenty of options, all "base" in nature.

Best regards,

Paul S

|

|

|

|

Posted by N-set on

02-06-2017

|

Paul, I'm using this one: http://uk.farnell.com/kontakt-chemie/kontakt-pcc/flux-remover-aerosel-200ml/dp/2532504

|

|

|

|

Posted by Paul S on

02-06-2017

|

No doubt there are any number of ways to get a nice coating of natural shellac over clean, chemically neutral, soldered connections, but you did mention you have "bubbles", and there must be "chemical" reasons for this. I looked up the cleaner you are using, and there is no indication that it is alkaline, which a specialized flux remover should be, as far as I know. One first needs to remove the residual rosin (including scraping, as necessary), then one needs to neutralize the residual acids (from the flux). Then one can clean it in a way that leaves it "neutral". Then the traditional shellac (with denatured alcohol) can be applied in thin layers.

Here's a spec sheet I found on your cleaner. You can check your cleaner with litmus strips, of course. However you manage it, you are aiming at a clean and chemically "neutral" joint under the shellac, and no "bubbles".

http://docs-asia.electrocomponents.com/webdocs/136b/0900766b8136b1bf.pdf

Best regards,

Paul S

|

|

|

|

Posted by N-set on

02-06-2017

|

Paul, thank you for your explanations. No idea if PCC is alkaline but according to its manufacturer it has some isoalkanes and isopropyl. Visually it does remove it quickly (also my Cardas solder is not leaving much of a flux): http://www.kontaktchemie.com/KOC/KOCproductdetail.csp?product=KONTAKT%20PCC

I'll ass-u-me that the bubbles are due to the slowly evaporating isopropyl in too thick applications of the coating and I'll leave the phonocorrector with the bubbles. I have no intention to go cleaning all the joints. Will try the denaturated alco solution with next solderings.

Thanks again,

Jarek

|

|